The frozen food industry runs on precision. From production to packaging and storage, every detail matters—especially when it comes to tracking product batches and ensuring safety compliance. One mistake in labeling or traceability can lead to product recalls, compliance issues, or even a loss of consumer trust.

That’s why QR batch code tracking has become a game-changer for frozen food manufacturers. Unlike traditional batch codes printed as plain text, QR batch codes offer an advanced, scannable solution that connects each frozen food item to real-time data—such as production dates, expiry information, storage temperature records, and shipment details.

In this article, you’ll learn why frozen food companies need QR code batch tracking, how it works, how to set it up easily, and why QuitURL is the best QR code generator for your food tracking needs.

Why Frozen Food Companies Need QR Code Batch Tracking

The global frozen food market is growing rapidly—but so are safety regulations and customer expectations. Consumers want transparency, and authorities demand accurate traceability. QR batch codes provide both.

Here’s why every frozen food brand—small or large—should use QR batch tracking:

1. Full Product Traceability

QR batch codes allow producers to track every item’s journey from the factory to the freezer aisle. By scanning the code, companies can instantly view which batch the item belongs to, when it was produced, and where it was distributed.

This is crucial during audits, recalls, or quality checks. Instead of combing through spreadsheets or printed logs, one simple scan reveals the entire product history.

2. Compliance with Food Safety Regulations

Food safety authorities worldwide (such as FDA, FSSAI, and EFSA) require batch traceability for frozen and perishable goods. QR code tracking helps manufacturers stay compliant with digital records that are easy to access and verify.

It simplifies the documentation needed for HACCP, ISO 22000, and BRCGS certifications.

3. Rapid Recall Management

When an issue arises (such as contamination or incorrect labeling), QR batch codes make recall management faster and more targeted.

Instead of recalling an entire product line, you can isolate and recall only the affected batches—minimizing waste and financial losses.

4. Real-Time Data and Transparency

Each QR batch code can store or link to live data, such as:

- Production date and time

- Ingredient source

- Temperature during storage

- Expiration and best-before date

- Distribution details

This builds consumer trust and provides internal teams with better data visibility.

5. Enhanced Supply Chain Efficiency

Logistics and warehouse teams can quickly identify batches using QR scans instead of manual lookups. This saves time, reduces human error, and streamlines stock rotation (FIFO/LIFO).

6. Consumer Engagement

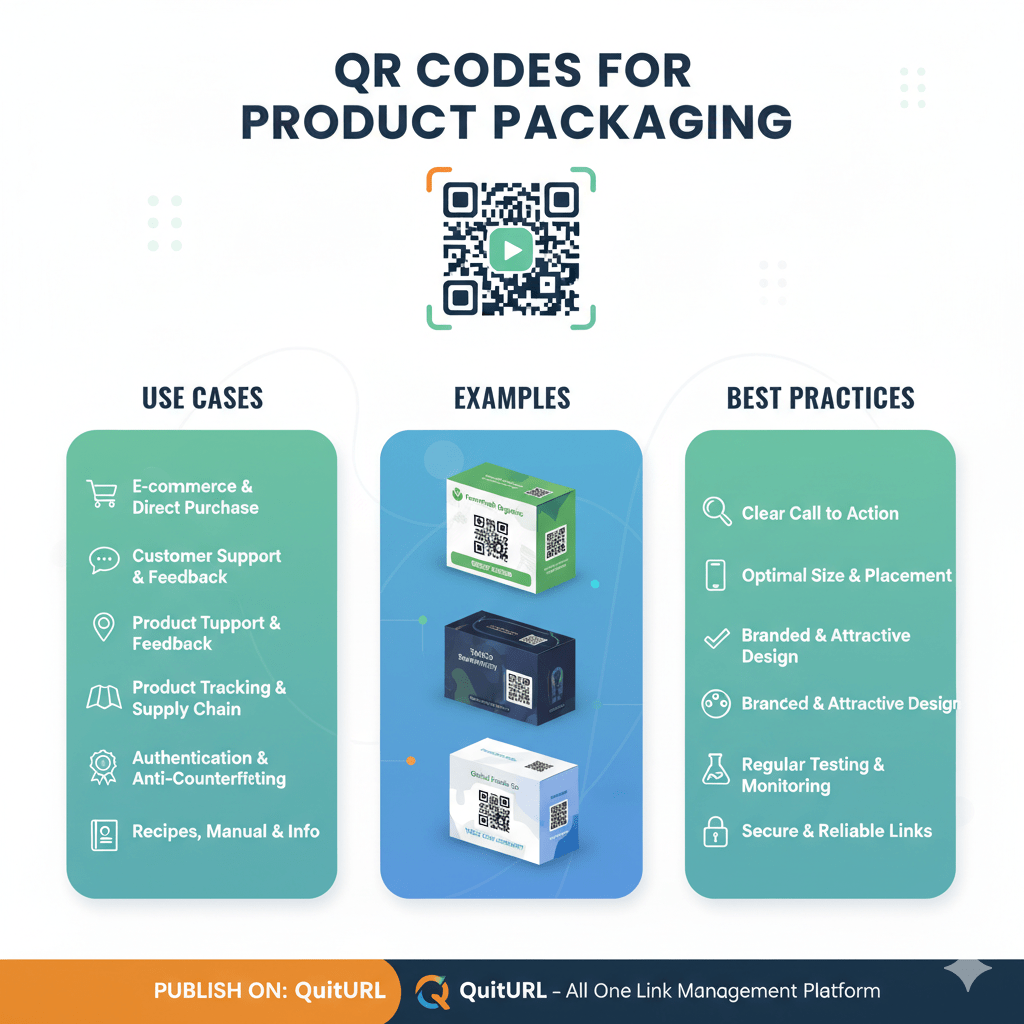

QR codes on packaging don’t just help businesses—they also add value for customers. Shoppers can scan the code to check product freshness, authenticity, recipes, and nutritional information. This boosts brand credibility and customer satisfaction.

How Do QR Batch Codes Work for Tracking Frozen Food?

QR batch code tracking combines unique identification, data storage, and digital monitoring. Here’s how it works step by step:

1. Assign a Unique Batch Code

Each production batch (e.g., “Batch 2025A”) is assigned a unique identifier. This code is digitally linked to production data—like the date, ingredients, and plant location.

2. Generate QR Codes for Each Batch

Using a QR code generator (like QuitURL), manufacturers convert the batch data into a QR code. This can be static (fixed) or dynamic (editable).

- Static QR code: Data is permanently embedded.

- Dynamic QR code: Links to a database or webpage that can be updated anytime without reprinting new labels.

Dynamic codes are ideal for frozen food because they allow updates in storage, shipping, or temperature data even after packaging.

3. Print and Apply QR Codes

The generated QR codes are printed on packaging, cartons, or labels. Modern printers and labelers can easily integrate with QuitURL’s system to auto-generate and print codes in bulk.

4. Scan and Store Data During Each Stage

At each stage—production, inspection, storage, and distribution—the QR code is scanned to log time-stamped data. These scans are automatically uploaded to a cloud database.

This helps teams track exactly when a product was made, where it was sent, and how it was handled.

5. Use the Data for Quality Control and Recall

If there’s ever an issue, the QR code allows teams to trace the exact batch and take quick action. The database provides complete visibility into every touchpoint.

Easily Set Up Batch QR Code Tracking for Frozen Food

Setting up a QR batch code tracking system may sound complex, but with tools like QuitURL, it’s surprisingly easy. Here’s how to begin:

Step 1: Identify Your Tracking Needs

Decide what information each QR batch code should hold. Examples include:

- Batch or lot number

- Production date and line

- Expiry or “best before” date

- Temperature records

- Distribution point

List the exact data points you want to store or link to.

Step 2: Choose a Reliable QR Code Generator

You’ll need a professional-grade QR code platform that can handle bulk creation, dynamic updates, and analytics.

QuitURL is perfect for this purpose (details below).

Step 3: Generate QR Codes for Each Batch

Once your data is ready, generate unique QR codes for every batch or product line. QuitURL allows you to create both static and dynamic QR codes with custom branding and logos.

Step 4: Integrate QR Codes Into Your Packaging Workflow

Work with your printing and labeling team to include QR codes on every product label. You can print them on:

- Product pouches

- Shipping boxes

- Frozen trays

- Cartons or pallets

Step 5: Link the QR Codes to Your Database

QuitURL can link each QR code to your internal tracking system, so when scanned, it shows relevant data like batch status, temperature logs, and expiration dates.

Step 6: Monitor and Analyze Scans

Once products are distributed, your QA and logistics teams can scan codes to view and log data.

QuitURL’s analytics dashboard shows when and where scans occur, helping you monitor product performance and distribution.

Step 7: Update Data Anytime

If a product’s data changes—say, a new storage condition or updated safety certification—you can easily edit dynamic QR codes in QuitURL without reprinting.

Why QuitURL is the Best QR Code Generator for Frozen Food Tracking

When it comes to frozen food traceability, not all QR code platforms are built the same. You need a generator that’s secure, dynamic, and analytics-driven—and that’s where QuitURL stands out.

Here’s why QuitURL is the best QR code generator for batch tracking in the frozen food industry:

1. Dynamic QR Codes for Real-Time Updates

Frozen food data can change frequently—especially temperature logs or shipment details. QuitURL’s dynamic QR codes let you update data anytime without reprinting new labels.

2. Bulk QR Code Generation

You can create hundreds or thousands of QR codes for different batches with just a few clicks—perfect for high-volume frozen food production lines.

3. Advanced Scan Analytics

QuitURL provides deep analytics showing scan location, device, language, and time, helping you monitor your supply chain and customer engagement.

4. Team Collaboration

Assign team members access to generate, manage, and track QR codes collaboratively within one secure dashboard.

5. Secure & Compliant

QuitURL is powered by Deep Thinkar LLC, ensuring SSL encryption, data privacy, and 99% uptime SLA, making it enterprise-ready for compliance-sensitive industries like food manufacturing.

6. Custom Branding and Design

Make your QR codes look professional with your brand logo, color palette, and unique shape—enhancing both product design and consumer trust.

7. Affordable for All Businesses

Whether you’re a startup or an enterprise frozen food brand, QuitURL’s pricing is flexible and far more affordable than other enterprise QR solutions.

8. API Integration for Automation

QuitURL offers a developer API that can integrate directly into your ERP, inventory, or QA systems—automating QR code creation and tracking at scale.

9. Multi-Language and Geo Targeting

QuitURL supports geo-based and language-based redirection, allowing companies to customize content for different countries or regional packaging.

👉 Start managing your frozen food batches smarter today at QuitURL.com — your all-in-one QR Code Generator for batch tracking, quality control, and traceability.

FAQs

1. What is a batch QR code?

A batch QR code is a unique scannable code assigned to a specific production batch of products. It links to details like production date, ingredients, or storage data.

2. Can QR batch codes track temperature or expiry?

Yes. QR codes can link to databases that store real-time temperature, expiry dates, and storage conditions, making them ideal for frozen food tracking.

3. How are QR codes better than traditional batch labels?

Unlike plain-text batch labels, QR codes store more data, are scannable, and allow digital traceability and analytics.

4. Can customers scan the QR codes too?

Yes. You can choose to make your QR codes public, letting customers scan and verify authenticity, view product details, or even access recipes.

5. Why use QuitURL for frozen food tracking?

QuitURL offers dynamic, secure, and trackable QR codes that can be updated anytime. It also includes analytics, branding, and API support—making it the best option for food manufacturers.

Conclusion

In a competitive and regulated industry like frozen food, traceability and transparency are non-negotiable. QR batch code tracking empowers manufacturers to track every product with precision, simplify recalls, and maintain the highest standards of safety and compliance.

By adopting this digital system, companies not only protect their brand but also enhance consumer trust. And when it comes to generating reliable, dynamic, and secure QR codes, QuitURL leads the way.

With features like real-time updates, analytics, API integration, and branding, QuitURL transforms how frozen food businesses manage batch tracking—from production to the customer’s freezer.

🚀 Start your QR batch tracking journey today with QuitURL.com and experience a smarter, safer, and more efficient way to manage frozen food quality.